PART 2 AThttp://drugsynthesisint.blogspot.in/p/vir-series-hep-c-virus-22.html

1 TEGOBUVIR

2 DANOPREVIR

3 CILUPREVIR

4 SOVAPREVIR

5 VEDROPREVIR

6 VANIPREVIR

7 NARLAPREVIR

8 DELDEPREVIR, NECEPREVIR

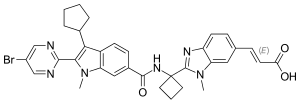

9 FALDAPREVIR

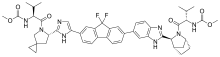

10 LEDIPASVIR

11DACLATASVIR

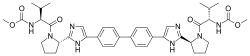

12 DELEOBUVIR

13 FILIBUVIR

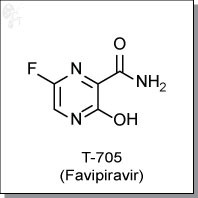

14 FAVIPIRAVIR

15 ASUNAPREVIR

SEE MORE AT

http://drugsynthesisint.blogspot.in/p/vir-series-hep-c-virus-22.html

http://drugsynthesisint.blogspot.in/p/vir-series-hep-c-virus-22.html

1 TEGOBUVIR

tegobuvir

tegobuvir

1 TEGOBUVIR

2 DANOPREVIR

3 CILUPREVIR

4 SOVAPREVIR

5 VEDROPREVIR

6 VANIPREVIR

7 NARLAPREVIR

8 DELDEPREVIR, NECEPREVIR

9 FALDAPREVIR

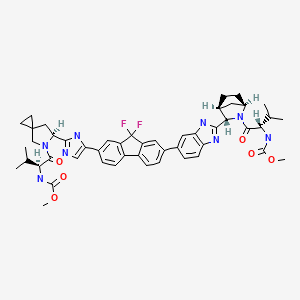

10 LEDIPASVIR

11DACLATASVIR

12 DELEOBUVIR

13 FILIBUVIR

14 FAVIPIRAVIR

15 ASUNAPREVIR

SEE MORE AT

http://drugsynthesisint.blogspot.in/p/vir-series-hep-c-virus-22.html

http://drugsynthesisint.blogspot.in/p/vir-series-hep-c-virus-22.html

VIR SERIES ..HEP C VIRUS 2/2

1 TEGOBUVIR

TEGOBUVIR

A non-structural protein 5B polymerase inhibitor

for Treatment of chronic hepatitis C

for Treatment of chronic hepatitis C

5-[6-[2,4-Bis(trifluoromethyl)phenyl]pyridazin-3-ylmethyl]-2-(2-fluorophenyl)-5H-imidazo[4,5-c]pyridine

CHEMICAL NAMES

1. 5H-Imidazo[4,5-c]pyridine, 5-[[6-[2,4-bis(trifluoromethyl)phenyl]-3-pyridazinyl]methyl]-

2-(2-fluorophenyl)-

2-(2-fluorophenyl)-

2. 5-({6-[2,4-bis(trifluoromethyl)phenyl]pyridazin-3-yl}methyl)-2-(2-fluorophenyl)-5H-

imidazo[4,5-c]pyridine

imidazo[4,5-c]pyridine

MOLECULAR FORMULA C25H14F7N5

MOLECULAR WEIGHT 517.4

MANUFACTURER Gilead Sciences, Inc.

CODE DESIGNATION

- GS 333126

- GS 9190

- GS-333126

- GS-9190

- Tegobuvir

- UNII-5NOK5X389M

CAS REGISTRY NUMBER 1000787-75-6

GS-9190, an RNA-directed RNA polymerase (NS5B) inhibitor, is in phase II clinical evaluation at Gilead for the treatment of hepatitis C virus (HCV) infection. A clinical trial with GS-9190 in combination with peginterferon alfa-2a and ribavirin and with GS-9451 or with GS-9256 in treatment-naive subjects with chronic genotype 1 HCV infection was discontinued due to serious adverse events.

Gilead (Originator)

Katholieke Universiteit Leuven (Originator)

Katholieke Universiteit Leuven (Originator)

……………………………………….

PATENTS

WO 2005063744

WO 2008005519

WO 2009009001

WO 2010151488

WO 2010151487

WO 2010151472

WO 2011072370

WO 2011156757

WO 2012087596

WO 2013101550

Hebner CM, Han B, Brendza KM, Nash M, Sulfab M, Tian Y, Hung M, Fung W, Vivian RW, Trenkle J, Taylor J, Bjornson K, Bondy S, Liu X, Link J, Neyts J, Sakowicz R, Zhong W, Tang H, Schmitz U.

PLoS One. 2012;7(6):e39163. doi: 10.1371/journal.pone.0039163. Epub 2012 Jun 13.

Wong KA, Xu S, Martin R, Miller MD, Mo H.

Virology. 2012 Jul 20;429(1):57-62. doi: 10.1016/j.virol.2012.03.025. Epub 2012 Apr 28.

Zeuzem S, Buggisch P, Agarwal K, Marcellin P, Sereni D, Klinker H, Moreno C, Zarski JP, Horsmans Y, Mo H, Arterburn S, Knox S, Oldach D, McHutchison JG, Manns MP, Foster GR.

Hepatology. 2012 Mar;55(3):749-58. doi: 10.1002/hep.24744.

Shih IH, Vliegen I, Peng B, Yang H, Hebner C, Paeshuyse J, Pürstinger G, Fenaux M, Tian Y, Mabery E, Qi X, Bahador G, Paulson M, Lehman LS, Bondy S, Tse W, Reiser H, Lee WA, Schmitz U, Neyts J, Zhong W.

Antimicrob Agents Chemother. 2011 Sep;55(9):4196-203. doi: 10.1128/AAC.00307-11. Epub 2011 Jul 11.

- ……………………..

- http://www.google.com/patents/WO2013040492A2

- ompound 1 can be prepared using synthetic methods and intermediates like those described in US 7,754,720. Compound 1 can also be prepared as described in the following Example.

- Compound 1 is:Compound 1 may also be referred to as 5-((6-(2,4-bis(trifluoromethyl)phenyl)pyridazin-3-yl)methyl)-2-(2-fluorophenyl)-5H-imidazo[4,5-c]pyridine, 5-[[6-[2,4-bis (trifluoromethyl)phenyl]pyridazin=3-yl]methyl]-2-(2-fluorophenyl).

- Example 1 : 5-({6-[2,4-bis(trifluoromethyl)phenyl]pyridazin-3-yl}methyl)-2-(2-fluorophenyl)-5H- imidazo[4,5-c]pyridiCompound 103 was dissolved in dimethoxyethane (DME). To this solution was added 2,4-bis(trifluromethyl)phenylboronic acid 105 and a 2N aq. Na2C03 solution. To the resulting biphasic mixture was added Pd(PPh3)4 and the reaction was then heated at 80°C for 72 hrs. The reaction was cooled to room temperature and filtered through Celite and the Celite washed with EtOAc. The filtrate was concentrated in vacuo. The residue was purified on 6g Si02 using MeOH/CH2CI2 to elute compound. The compound thus obtained was contaminated with PPh3(0). The product was repurified on a 1 mm Chromatotron plate with 0 to 5%MeOH/CH2CI2 in 1 % steps. The pure fractions were combined and concentrated in vacuo, then dried on high vacuum for 12 hrs. 11.8 mg of the free base of compound 1 was obtained with no PPh3 contamination. 1H NMR (300MHz,CD3OD) δ 6.20 (s, 2), 7.32 (m, 3), 7.52 (m, 1 ), 7.78 (d, 1), 7.89 (d, 1), 7.95 (s, 2), 8.15 (m, 3), 8.35 (d, 1), 9.12 (s, 1); LC/MS M+H = 518.The intermediate compound 104 was prepared as follows, a. Preparation of Compound 10101 102To a solution of the commercially available starting material 101 in CHCI3, trichloroisocyanuric acid (TCCA) was added at 60°C. Then the solution was stirred for 1.5 hrs, cooled, and filtered with HiFlo-Celite. The filtrate was concentrated and dried with vacuum. The yield was 5.037 g of compound 102. b. Preparation of Compound 104.102 104To a solution of compound 103 in DMF (dimethylformamide), NaOH was added.Compound 102 was dissolved in DMF (20 mL) and added to the solution slowly. The reaction was stirred for 3 hrs, was diluted with water and extracted with EtOAc. The organic layer was dried with Na2S0 . The solvent was removed and the product recrystallized withdichloromethane. The yield was 5.7 g of compound 103.

- ……………………………

- US7754720

- Example 1a Synthesis of 5-({6-[2,4-bis(trifluoromethyl)phenyl]pyridazin-3-yl}methyl)-2-(2-fluorophenyl)-5H-imidazo[4,5-c]pyridineIn this method, dimethoxyethane or its related solvents, all having the general formula R1OR2O(R4O)aR3 wherein each of R1, R2, R3 and R4 are independently selected from C1-C6 alkyl and a is 0 or 1, have been found to be particularly advantageous over the conventional solvent DMF. Typically, each of R1, R2, R3 and R4 are independently C1-C2 alkyl and usually a is 0. C1-C6 alkyl includes fully saturated primary, secondary or tertiary hydrocarbon groups with 1 to 6 carbon atoms and thereby includes, but is not limited to methyl, ethyl, propyl, butyl, etc.Step 1

Compound MW Amount mmoles Equivalents SM 128.56 5 g 38.9 1 TCCA 232.41 3.62 g 15.6 0.4 CHCl3 130 ml To a solution of the commercially available starting material (SM) in CHCl3, trichloroisocyanuric acid (TCCA) was added at 60° C. Then the solution was stirred for 1.5 hrs., cooled down and filtered with HiFlo-Celite. The filtrate was concentrated and dried with vacuum. The yield was 5.037 g.Step 2Compound MW Amount mmoles Equivalents S.M. 163 5.073 g 31.12 1 Core 213.2 6.635 g 31.12 1 NaOH (10%) 40 1.245 g 31.12 1 DMF 320 ml To a solution of core (obtained as described in literature in DMF (dimethylformamide), NaOH was added. Then SM for this step (obtained from step 1) was dissolved in DMF (20 ml) and added to the solution slowly. The reaction was stirred for 3 hrs, was diluted with water and extracted with EtOAc. The organic layer was dried with Na2SO4. The solvent was removed and the product recrystallized with DCM (dichloromethane). The yield was 5.7 g.Step 3Compound MW Amount Moles Equivalents A 453.79 95 mg 0.209 1 DME 500 ul 2 N aq. Na2CO3 313ul 0.626 3 2,4-bisCF3- 257.93 80.9 mg 0.313 1.5 phenylboronic acid Pd(PPh3)4 1155 12 mg 0.0104 0.05 Compound A was dissolved in dimethoxyethane (DME). To this solution was added 2,4-bis(trifluromethyl)phenylboronic acid and a 2N aq. Na2CO3 solution. To the resulting biphasic mixture was added Pd(PPh3)4 and the reaction was then heated at 80° C. for 72 hrs. The reaction was cooled to room temperature and filtered through Celite and the Celite washed with EtOAc. The filtrate was concentrated in vacuo. The residue was purified on 6 g SiO2 using MeOH/CH2Cl2 to elute compound. The compound thus obtained was contaminated with PPh3(O). The product was repurified on a 1 mm Chromatotron plate with 0 to 5% MeOH/CH2Cl2 in 1% steps. The pure fractions were combined and concentrated in vacuo, then dried on high vacuum for 12 hrs. 11.8 mg of the free base of compound (1) was obtained with no PPh3 contamination.1H NMR (300 MHz, CD3OD)6.20 (s, 2)7.32 (m, 3)7.52 (m, 1)7.78 (d, 1)7.89 (d, 1)7.95 (s, 2)8.15 (m, 3)8.35 (d, 1)9.12 (s, 1)LC/MS M+H=518Example 1b Synthesis of 5-({6-[2,4-bis(trifluoromethyl)phenyl]pyridazin-3-yl}methyl)-2-(2-fluorophenyl)-5H-imidazo[4,5-c]pyridineThis example is directed to an additional method for making compound (1), employing the following schemes.Methanesulfonic acid was added to 2-fluorobenzoic acid in a reactor with active cooling keeping T≦50° C. 3,4-Diaminopyridine was then added portionwise to this cooled slurry, keeping T≦35° C. The contents of the reactor were then heated to 50° C. Phosphorus pentoxide was added in a single charge. The reaction was then heated at 90-110° C. for at least 3 hours. The reaction was sampled for completion by HPLC analysis. The reaction was cooled to ambient temperature and water was added portionwise slowly to quench the reaction. The reaction was then diluted with water. In solubles were removed by filtration. The pH of the filtrate was adjusted to 5.5-5.8 with ammonium hydroxide. The reaction was allowed to self-seed and granulate for ˜4 hours at ambient temperature. The pH was then adjusted to 8.0-9.3 with ammonium hydroxide. The slurry was held at ambient temperature for at least 2 hours. The solids were isolated by filtration and washed with water, followed by IPE. The wet cake was dried in vacuo at not more than 60° C. until ≦1% water remains. The dry product is core (2).Summary of Materials M.W. Wt. Ratio Mole ratio 3,4-Diaminopyridine 109.13 1.0 1.0 2-Fluorobenzoic acid 140.11 1.4 1.1 Methanesulfonic acid 96.1 7.0 8.0 Phosphorus pentoxide 141.94 1.3 1.0 Water 18.02 40 — Isopropyl ether 102.17 5.0 — Ammonium hydroxide 35.09 ~10 — A solution of compound (2a) in 1,2-dichloroethane was heated to 40-45° C. Trichloroisocyanuric acid was added and the mixture was heated at 60-70° C. for at least 2 hours. The reaction was sampled for completion by HPLC analysis. The reaction was cooled to ambient temperature. Celite was added to absorb insolubles, then solids were removed by filtration. The filtrate was washed with 0.5 N sodium hydroxide solution. The organic layer was concentrated to lowest stirrable volume and displaced with DMF. Core (2) and 10% aqueous sodium hydroxide solution were added. The reaction was stirred at ambient temperature for at least 8 hours. The reaction was sampled for completion by HPLC analysis. An additional 10% charge of 10% sodium hydroxide solution was added to the reaction. The reaction was then charged into water to isolate the crude product. After granulating for at least 1 hour, the solids were isolated and washed with water and isopropyl ether. Ethyl acetate was added and refluxed (internal T=70-77° C.) for 1-5 hours to dissolve product, then cooled to 18-23° C. slowly over 4-8 hours. The reactor contents were agitated at 18-23° C. for 8-20 hours and solids collected by filtration and rinsed with ethyl acetate. Low melt (i.e., DSC about 220 degrees C.) amorphous compound (1) was discharged. Amorphous compound (1) was dissolved in ethyl acetate by heating at reflux (internal T=70-77° C.) for 1-5 hours. Water content is controlled to about 0.2% by azeotropically removing water (with ethyl acetate the upper limit on water content is about 0.6% by weight; at about 0.9% by weight water the amorphous material will reprecipitate and crystals will not be obtained). The reactor contents are cooled slowly to 18-23° C. over 4-8 hours, then agitated at 18-23° C. for 8-20 hours and solids collected by filtration. The solids were rinsed with ethyl acetate and dried in vacuo at not more than 60° C. to obtain the dry crystalline compound (1).Summary of Materials M.W. Wt. Ratio Mole ratio 3-chloro-6-methylpyridazine 128.56 1.0 1.0 2,4bis(trifluromethyl)phenylboronic 257.93 4.0 2.0 acid X-Phos 476.72 0.18 0.05 Palladium acetate 224.49 0.04 0.025 1,2-Dimethoxyethane 90.12 16.7 — Potassium carbonate 138.21 2.15 2.0 Water 18.02 7.8 — Copper iodide 190.45 0.037 0.025 Celite — 0.25 — Heptane 100.2 22.4 — Nuclear Magnetic Resonance (1H-, 13C-, and 19F-NMR) SpectraNuclear magnetic resonance (NMR) spectra of compound (1) is consistent with the proposed structure. The 13C, 19F, and 1H-NMR spectra of compound (1) in DMSO-d6 were measured using a Varian UnityInova-400 FT-NMR spectrometer. Spectra are shown in the table below. The NMR chemical shift assignments were established using 2D correlation experiments (COSY, HSQC, HMBC and HSQCTOCSY).1H- and 13C-NMR Chemical Shift Assignments for Compound (1) Reference StandardAtom δC/ppm (DMSO-d6) δF/ppm (DMSO-d6) δH/ppm (DMSO-d6) 1A 140.16 2A 128.32 (qa, JCF = 32 Hz) 3A 123.61, m 8.24 (m, 1 H) 4A 130.27 (q, JCF = 34 Hz) 5A 129.54 (q, JCF = 3 Hz) 8.22 (m, 1 H) 6A 133.36 7.88 (m, 1 H) 7A 123.20 (q, JCF = 273 Hz) −56.4b 8A 123.02 (q, JCF = 275 Hz) −62.0b 1B 158.76 2B 128.16 8.01 (d, 1 H, J = 8.4 Hz) 3B 126.20 7.95 (d, 1 H, J = 8.8 Hz) 4B 157.70 5B 60.49 6.17 (s, 2 H) 2C 131.86 8.31 (m, 1 H) 3C 112.63 7.86 (m, 1 H) 4C 155.44 6C 168.11 (d, JCF = 6 Hz) 8C 145.08 9C 133.06 9.25 (s, 1 H) 1D 123.11 (d, JCF = 10 Hz) 2D 160.46 (d, JCF = 254 Hz) −111.7 3D 116.59 (d, JCF = 22 Hz) 7.29 (m, 1 H) 4D 130.84 (d, JCF = 8 Hz) 7.46 (m, 1 H) 5D 124.13 (d, JCF = 4 Hz) 7.31 (m, 1 H) 6D 131.72 (d, JCF = 2 Hz) 8.35 (m, 1 H) amultiplicity, s: singlet, d: doublet, q: quartet, m: multiplet binterchangeable signals

...............................................

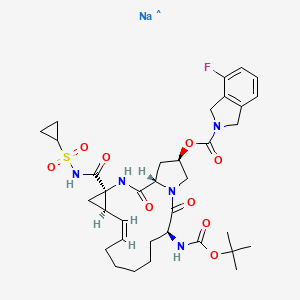

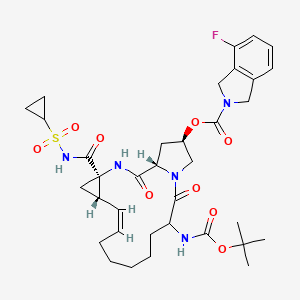

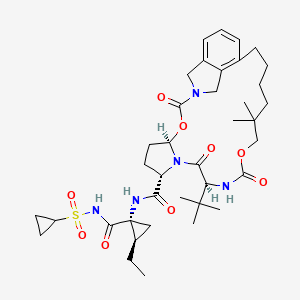

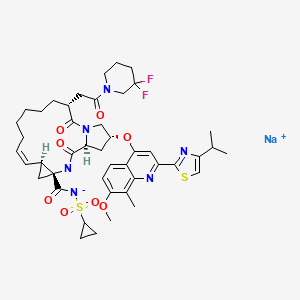

2 DANOPREVIR

DanoprevirDanoprevir(ITMN-191) is a peptidomimetic inhibitor of the NS3/4A protease of hepatitis C virus (HCV) with IC50 of 0.2-3.5 nM, inhibition effect for HCV genotypes 1A/1B/4/5/6 is ~10-fold higher than 2B/3A. Phase 2.Array BioPharma (Originator)

DanoprevirDanoprevir(ITMN-191) is a peptidomimetic inhibitor of the NS3/4A protease of hepatitis C virus (HCV) with IC50 of 0.2-3.5 nM, inhibition effect for HCV genotypes 1A/1B/4/5/6 is ~10-fold higher than 2B/3A. Phase 2.Array BioPharma (Originator)RG7227 ITMN-191 RO5190591 2H-Isoindole-2-carboxylic acid, 4-fluoro-1,3-dihydro-, (2R,6S,12Z,13aS,14aR,16aS)-

14a-[[(cyclopropylsulfonyl)amino]carbonyl]-6-[[(1,1-dimethylethoxy)carbonyl]amino]-

1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydro-5,16-

dioxocyclopropa[e]pyrrolo[1,2-a][1,4]diazacyclopentadecin-2-yl ester2. (2R,6S,12Z,13aS,14aR,16aS)-14a-[(cyclopropylsulfonyl)carbamoyl]-6-{[(1,1-

dimethylethoxy)carbonyl]amino}-5,16-dioxo-

1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-

a][1,4]diazacyclopentadecin-2-yl 4-fluoro-1,3-dihydro-2H-isoindole-2-carboxylate

Treatment of hepatitis CMOLECULAR FORMULA C35H46FN5O9SMOLECULAR WEIGHT 731.8MANUFACTURER GenentechCODE DESIGNATION R05190591CAS REGISTRY NUMBER 850876-88-9, 916881-67-9Danoprevir(ITMN-191) is a peptidomimeticITMN-191 (R-7227), a macrocyclic protease inhibitor, is in phase II clinical evaluation for the treatment of chronic hepatitis C virus (HCV) infection as monotherapy and in combination with Pegasys(R) (pegylated interferon alpha-2a) and Copegus(R) (ribavirin). The product candidate is also being evaluated in combination with R-7128 in treatment-naive patients infected with HCV genotype 1.Danoprevir (ITMN-191; RG-7227), under development by InterMune Inc and Roche Holding AG, is a promising, potent NS3/4A protease inhibitor for the oral treatment of HCV infection. Preclinical data demonstrated that danoprevir binds with high affinity and dissociates slowly from the HCV NS3 protease, allowing high liver drug exposure with only modest plasma drug exposure.In 2006, originator InterMune and licensee Roche entered into an exclusive worldwide collaboration agreement to develop and commercialize products from InterMune’s hepatitis C (HCV) protease inhibitor program, including ITMN-191. In 2010, the licensing agreement was terminated. Also in 2010, Roche acquired worldwide development and commercialization rights to R-7227 from InterMune. Preclinical pharmacokinetic results support the exploration of twice-daily oral dosing in HCV.A phase Ib, ‘IFN-free’ clinical trial demonstrated that danoprevir, combined with the HCV polymerase inhibitor RG-7128 (Pharmasset Inc/Roche Holding AG), was effective in reducing HCV-RNA levels in a large proportion of treatment-naïve patients with HCV infection and in approximately half of previously non-responsive patients with HCV-1 infection, without resistance or safety concerns. In a phase IIb trial in treatment-naïve patients with HCV-1 infection, danoprevir plus pegylated IFNalpha2a and ribavirin resulted in undetectable levels of HCV-RNA in the majority of patients, without any evidence of viral resistance; however, the high-dose danoprevir arm was prematurely terminated because of grade 4 ALT elevations. Phase I trials have also demonstrated that ritonavir boosting improved the pharmacokinetic profile of danoprevir; therefore, at the time of publication, a phase IIb trial to evaluate ritonavir-boosted, low-dose danoprevir in combination with RG-7128 was planned. (source:inhibitor of the NS3/4A protease of hepatitis C virus (HCV) with IC50 of 0.2-3.5 nM, inhibition effect for HCV genotypes 1A/1B/4/5/6 is ~10-fold higher than 2B/3A. Phase 2.SODIUM SALTHERAPEUTIC CLAIM Treatment of hepatitis CCHEMICAL NAMES1. 2H-Isoindole-2-carboxylic acid, 4-fluoro-1,3-dihydro-, (2R,6S,12Z,13aS,14aR,16aS)-

14a-[[(cyclopropylsulfonyl)amino]carbonyl]-6-[[(1,1-dimethylethoxy)carbonyl]amino]-

1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydro-5,16-dioxocyclopropa

[e]pyrrolo[1,2-a][1,4]diazacyclopentadecin-2-yl ester, sodium salt (1:1)2. sodium (cyclopropylsulfonyl){[(2R,6S,12Z,13aS,14aR,16aS)-6-{[(1,1-dimethylethoxy)

carbonyl]amino}-2-{[(4-fluoro-1,3-dihydro-2H-isoindol-2-yl)carbonyl]oxy}-5,16-dioxo-

1,2,3,6,7,8,9,10,11,13a,14,15,16,16a-tetradecahydrocyclopropa[e]pyrrolo[1,2-

a][1,4]diazacyclopentadecine-14a(5H)-yl]formyl}azanideMOLECULAR FORMULA C35H45FN5NaO9SMOLECULAR WEIGHT 753.8SPONSOR GenentechCODE DESIGNATION- Danoprevir sodium

- ITMN-191

- R 7227 sodium

- R7227

- RO 5190591-001

- RO5190591-001

- UNII-217RJI972K

CAS REGISTRY NUMBER 916826-48-7DANOPREVIR SODIUM

The HCV protease mediates the cleavage of the HCV polyprotein to release the functional proteins that are essential for viral propagation. The inhibition of the HCV protease activity is expected to block HCV replication in infected host cells. Numberous HCV protease inhibitors have been identified. Non- limiting examples of HCV protease inhibitors are described in U.S. Patent Application Pub. Nos. 20040106559, 20040180815, 20040266668, 2004038872, 20050090432, 20050267018, 20070054842, 20070281885, 2007299078, 20080032936, 20080125444, 20080279821, 20090111757, 20090148407, 20090202480, 20090269305, 20090285773, 20090285774, 20100081700, 20100144608, 2010018355, 20100183551, 20100221217, 20100260710, 20100286185 and 20110135604, and U.S. Patent Nos. 6608027, 6767991, 7091184, 7119072, 7544798, 7642235 and 7829665, as well as WO2007014919, WO2007014926, WO2008046860, WO2008095058,………………………………danoprevirpatents and journal ref1. WO 2005037214..2. WO 20050954033. WO 2007015824..4. WO 20081289215. WO 20090805426. WO 20091428427. WO 20100155458. WO 20130794249. WO 201206268510.WO 201310663111. Concise asymmetric synthesis of a (1R,2S)-1-amino-2-vinylcyclopropanecarboxylic acid-derived sulfonamide and ethyl ester

Org Biomol Chem 2013, 11(39): 6796http://pubs.rsc.org/en/content/articlelanding/2013/ob/c3ob41394b/unauth#!divAbstract12.J. Med. Chem., Article ASAP,DOI: 10.1021/jm400164cKazmierski WM, Hamatake R, Duan M, Wright LL, Smith GK, Jarvest RL, Ji JJ, Cooper JP, Tallant MD, Crosby RM, Creech K, Wang A, Li X, Zhang S, Zhang YK, Liu Y, Ding CZ, Zhou Y, Plattner JJ, Baker SJ, Bu W, Liu L.J Med Chem. 2012 Apr 12;55(7):3021-6. doi: 10.1021/jm201278q. Epub 2012 Apr 3.Duan M, Kazmierski W, Crosby R, Gartland M, Ji J, Tallant M, Wang A, Hamatake R, Wright L, Wu M, Zhang YK, Ding CZ, Li X, Liu Y, Zhang S, Zhou Y, Plattner JJ, Baker SJ.Bioorg Med Chem Lett. 2012 Apr 15;22(8):2993-6. doi: 10.1016/j.bmcl.2012.02.039. Epub 2012 Feb 22.……………….J. Med. Chem., Article ASAPDOI: 10.1021/jm400164c (2R,6S,13aS,14aR,16aS,Z)-6-(tert-Butoxycarbonylamino)-14a-(cyclopropylsulfonylcarbamoyl)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-a][1,4]diazacyclopentadecin-2-yl 4-fluoroisoindoline-2-carboxylate (49)

(2R,6S,13aS,14aR,16aS,Z)-6-(tert-Butoxycarbonylamino)-14a-(cyclopropylsulfonylcarbamoyl)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-a][1,4]diazacyclopentadecin-2-yl 4-fluoroisoindoline-2-carboxylate (49)

1H NMR (500 MHz, acetone-d6) δ 10.70 (br s, 1 H), 8.34 (d, 1 H), 7.39–7.33 (m, 1 H), 7.20 (d, 1 H), 7.10–7.02 (m, 2 H), 6.13 (d, 1 H), 5.70 (q, 1 H), 5.44 (br s, 1 H), 4.99 (t, 1H), 4.78–4.59 (m, 5 H), 4.18–4.08 (m, 1 H), 3.88–3.81 (m, 1 H), 2.86–2.78 (m, 3 H), 2.71–2.60 (m, 1 H), 2.52–2.35 (m, 3 H), 1.92–1.81 (m, 2 H), 1.75 (t, 1 H), 1.61–1.14 (m, 17 H), 1.04–0.95 (m, 2 H). 13C NMR (DMSO-d6, 100 MHz) δ174.0, 172.3, 170.8, 157.5 (d, J = 244 Hz), 155.8, 154.0, 140.9 (d, J = 64.8 Hz), 130.6, 130.2, 129.6, 123.8 (d, J = 55.7 Hz), 119.6, 114.4 (d, J = 18.3 Hz), 78.4, 74.7, 59.7, 53.4, 52.7, 52.4, 49.4 (d, J = 37.1 Hz), 44.6, 34.9, 31.8, 30.4, 28.8, 28.6, 27.0, 25.7, 22.6, 4.8. APCI MS m/z730.4 (M – 1).………………………………………………………..Bioorg Med Chem Lett. 2012 Apr 15;22(8):2993-6. doi: 10.1016/j.bmcl.2012.02.039. Epub 2012 Feb 22.…………………………..PICK UP 12 REF COMPD FROM LIST= DANOPREVIR

NMR AND SYNExample 58 Synthesis of Compound 12-RefCompound 11-Ref (0.18 mmol) was dissolved in 10 mL anhydrous dichloromethane, EDCI (69.8 mg, 0.36 mmol, 2 eq.) was added and stirred at room temperature overnight until completed. The reaction mixture was worked out and concentrated.The obtained solid was dissolved in 10 mL of anhydrous dichloromethane, DBU (61.0 mg, 0.40 mmol) and RSO2NH2 (0.363 mmol, R=cyclopropyl) were added and stirred at room temperature overnight until completed. The reaction mixture was worked out and purified by flash column to obtain the product 12-Ref (62 mg; Yield: 53%).1H-NMR for the product 12-Ref (CDCl3, 500 MHz): δ 10.28-10.29 (d, 1H), 6.87-7.07 (m, 3H), 5.72-5.74 (m, 1H), 5.48 (br , 1H), 4.99-5.03 (m, 2H), 4.58-4.79 (m, 5H), 4.42 (m, 1H), 4.21 (m, 1H), 3.83-3.85 (m, 1H), 2.90-2.93 (m, 1H), 2.48-2.57 (m, 3H), 2.27-2.30 (m, 1H), 1.88-1.97 (m, 2H), 1.67-1.79 (m, 2H), 1.45-1.58 (m, 6H), 1.34 -1.40 (m, 2H), 1.27 (s, 4H), 1.24 (s, 5H), 1.08-1.15 (m, 2H), 0.91-0.94 (m, 1H). ESI-MS (M+H+): m/z calculated 732.3, founded 732.5.………………………..SYNTHESISFor certain NS3 inhibitors shown in this section, additional chemical transformations are utilized to obtain the final products. The preparations of two such examples are described for compounds 153 and 154 below:(2R,6S,13aS,14aR,16aS,Z)-6-(tert-botoxycarbonylamino)-2-(4-fluoroisoindoline-2-carbonyloxy)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-α][1,4]dizacyclopentadecine-14a-carboxylic acid (0.10 g, 0.16 mmol) and TEA (0.024 mL, 0.18 mmol) in THF (5 mL) was added ethyl carbonochlridate (0.016 mL, 0.17 mmol) at 0° C. The reaction was stirred at 0° C. for 2 hrs. Sodium boronhydride (0.012 g, 0.32 mmol) was added and the reaction was stirred at rt for 3 days. Water (5 mL) and ethyl acetate (10 mL) were added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was purified by column chromatography (ethyl acetate) to give the product (0.060 g, 61.4%) as white solid. 1H NMR (400 MHz, d6-DMSO) δ 8.47 (b, 1H), 7.35 (m, 1H), 7.10-7.20 (m, 2H), 7.03 (m, 1H), 5.47 (m, 1H), 5.28 (b, 1H), 4.98 (m, 1H), 4.67 (b, 4H), 4.56 (m, 1H), 4.46 (m, 1H), 4.26 (m, 1H), 3.92 (m, 1H), 3.66 (m, 2H), 3.16 (m, 1H), 2.67 (m, 1H), 2.21 (m, 2H), 1.80 (m, 1H), 1.68 (m, 1H), 1.30 (m, 8H), 1.11-1.20 (m, 9H), 0.85 (m, 1H), 0.77 (m, 1H).A solution of oxalyl chloride 90.045 mL, 0.089 mmol) in DCM (5 mL) at −78° C. was added a solution of DMSO (0.015 g, 0.020 mmol) in DCM (2 mL) dropwise over 2 ninytes. The reaction was stirred at −78° C. for 10 minutes and the a solution of (2R,6S,13aS,14aR,16aS,Z)-6-(tert-botoxycarbonylamino)-14a-(hydroxymethyl)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-α][1,4]dizacyclopentadecin-2-yl-4-fluoroisoindoline-2-carboxylate (0.050 g, 0.081 mmol) in DCM (2 mL) was added. After stirred at −78° C. for 40 min, TEA (0.051 mL, 0.37 mmol) was added. The reaction was warmed to rt, water (5 mL) was added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was dissolved in MeOH (5 mL) and ammonium hydroxide (0.085 g, 2.45 mmol) and acetic acid (0.014 mL, 0.25 mmol) were added. The reaction stirred at rt for 3 minutes. NaCNBH3 90.015 g, 0.245 mmol) was added and stirred at rt for 30 minutes. The MeOH was removed. DCM (20 mL) and saturated sodium bicarbonate (5 mL) was added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was dissolved in DCM (5 mL). TEA (0.017 mL, 0.122 mmol) was added and followed by the cyclopropanesulfonyl chloride (0.015 g, 0.098 mmol). The reaction was stirred at rt for 5 hrs. The solvent was removed. The residue was purified by column chromatography (ethyl acetate) to give the product (0.017 g, 28.2%) as white solid. 1H NMR (400 MHz, d6-DMSO) δ 8.52 (m, 1H), 7.35 (m, 1H), 7.02-7.20 (m, 4H), 5.56 (m, 1H), 4.99 (m, 1H), 4.97 (m, 1H), 4.67 (m, 2H), 4.66 (s, 2H), 4.46 (m, 1H), 4.24 (m, 1H), 3.92 (m, 1H), 3.67 (m, 1H), 3.46 (m, 1H), 2.74 (m, 1 h), 2.67 (m, 1H), 2.22 (m, 2H), 1.84 (m, 1H), 1.68 (m, 1H), 1.08-1.36 (m, 20H), 0.89 (m, 2H), 0.81 (m, 2H).………………………………………..

NMR AND SYNExample 58 Synthesis of Compound 12-RefCompound 11-Ref (0.18 mmol) was dissolved in 10 mL anhydrous dichloromethane, EDCI (69.8 mg, 0.36 mmol, 2 eq.) was added and stirred at room temperature overnight until completed. The reaction mixture was worked out and concentrated.The obtained solid was dissolved in 10 mL of anhydrous dichloromethane, DBU (61.0 mg, 0.40 mmol) and RSO2NH2 (0.363 mmol, R=cyclopropyl) were added and stirred at room temperature overnight until completed. The reaction mixture was worked out and purified by flash column to obtain the product 12-Ref (62 mg; Yield: 53%).1H-NMR for the product 12-Ref (CDCl3, 500 MHz): δ 10.28-10.29 (d, 1H), 6.87-7.07 (m, 3H), 5.72-5.74 (m, 1H), 5.48 (br , 1H), 4.99-5.03 (m, 2H), 4.58-4.79 (m, 5H), 4.42 (m, 1H), 4.21 (m, 1H), 3.83-3.85 (m, 1H), 2.90-2.93 (m, 1H), 2.48-2.57 (m, 3H), 2.27-2.30 (m, 1H), 1.88-1.97 (m, 2H), 1.67-1.79 (m, 2H), 1.45-1.58 (m, 6H), 1.34 -1.40 (m, 2H), 1.27 (s, 4H), 1.24 (s, 5H), 1.08-1.15 (m, 2H), 0.91-0.94 (m, 1H). ESI-MS (M+H+): m/z calculated 732.3, founded 732.5.………………………..SYNTHESISFor certain NS3 inhibitors shown in this section, additional chemical transformations are utilized to obtain the final products. The preparations of two such examples are described for compounds 153 and 154 below:(2R,6S,13aS,14aR,16aS,Z)-6-(tert-botoxycarbonylamino)-2-(4-fluoroisoindoline-2-carbonyloxy)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-α][1,4]dizacyclopentadecine-14a-carboxylic acid (0.10 g, 0.16 mmol) and TEA (0.024 mL, 0.18 mmol) in THF (5 mL) was added ethyl carbonochlridate (0.016 mL, 0.17 mmol) at 0° C. The reaction was stirred at 0° C. for 2 hrs. Sodium boronhydride (0.012 g, 0.32 mmol) was added and the reaction was stirred at rt for 3 days. Water (5 mL) and ethyl acetate (10 mL) were added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was purified by column chromatography (ethyl acetate) to give the product (0.060 g, 61.4%) as white solid. 1H NMR (400 MHz, d6-DMSO) δ 8.47 (b, 1H), 7.35 (m, 1H), 7.10-7.20 (m, 2H), 7.03 (m, 1H), 5.47 (m, 1H), 5.28 (b, 1H), 4.98 (m, 1H), 4.67 (b, 4H), 4.56 (m, 1H), 4.46 (m, 1H), 4.26 (m, 1H), 3.92 (m, 1H), 3.66 (m, 2H), 3.16 (m, 1H), 2.67 (m, 1H), 2.21 (m, 2H), 1.80 (m, 1H), 1.68 (m, 1H), 1.30 (m, 8H), 1.11-1.20 (m, 9H), 0.85 (m, 1H), 0.77 (m, 1H).A solution of oxalyl chloride 90.045 mL, 0.089 mmol) in DCM (5 mL) at −78° C. was added a solution of DMSO (0.015 g, 0.020 mmol) in DCM (2 mL) dropwise over 2 ninytes. The reaction was stirred at −78° C. for 10 minutes and the a solution of (2R,6S,13aS,14aR,16aS,Z)-6-(tert-botoxycarbonylamino)-14a-(hydroxymethyl)-5,16-dioxo-1,2,3,5,6,7,8,9,10,11,13a,14,14a,15,16,16a-hexadecahydrocyclopropa[e]pyrrolo[1,2-α][1,4]dizacyclopentadecin-2-yl-4-fluoroisoindoline-2-carboxylate (0.050 g, 0.081 mmol) in DCM (2 mL) was added. After stirred at −78° C. for 40 min, TEA (0.051 mL, 0.37 mmol) was added. The reaction was warmed to rt, water (5 mL) was added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was dissolved in MeOH (5 mL) and ammonium hydroxide (0.085 g, 2.45 mmol) and acetic acid (0.014 mL, 0.25 mmol) were added. The reaction stirred at rt for 3 minutes. NaCNBH3 90.015 g, 0.245 mmol) was added and stirred at rt for 30 minutes. The MeOH was removed. DCM (20 mL) and saturated sodium bicarbonate (5 mL) was added. The organic layer was separated, washed with brine and dried over sodium sulfate. After removal of solvent, the residue was dissolved in DCM (5 mL). TEA (0.017 mL, 0.122 mmol) was added and followed by the cyclopropanesulfonyl chloride (0.015 g, 0.098 mmol). The reaction was stirred at rt for 5 hrs. The solvent was removed. The residue was purified by column chromatography (ethyl acetate) to give the product (0.017 g, 28.2%) as white solid. 1H NMR (400 MHz, d6-DMSO) δ 8.52 (m, 1H), 7.35 (m, 1H), 7.02-7.20 (m, 4H), 5.56 (m, 1H), 4.99 (m, 1H), 4.97 (m, 1H), 4.67 (m, 2H), 4.66 (s, 2H), 4.46 (m, 1H), 4.24 (m, 1H), 3.92 (m, 1H), 3.67 (m, 1H), 3.46 (m, 1H), 2.74 (m, 1 h), 2.67 (m, 1H), 2.22 (m, 2H), 1.84 (m, 1H), 1.68 (m, 1H), 1.08-1.36 (m, 20H), 0.89 (m, 2H), 0.81 (m, 2H).……………………………………….. Hoffmann-La Roche and Genentech’s danoprevir/r (RG7227) is a twice-daily, ritonavir-boosted HCV protease inhibitor with activity against HCV genotypes 1, 4 and 6. DAUPHINE, an ongoing phase II trial in 421 treatment-naive people with HCV genotypes 1 and 4, is comparing doses (200, 100, and 50 mg danoprevir, boosted with 100 mg ritonavir, twice-daily) and response-guided therapy with danoprevir/r plus PEG-IFN/RBV. At 12 weeks after treatment completion, HCV RNA was undetectable in 86% of the highest-dosing arm, 77% of the 100 mg arm, and 65% of the 50 mg arm.Response to treatment in the 200 mg dosing arm did not differ according to HCV subtype or IL28B genotype; at 12 weeks after treatment completion, 88% of people with HCV subtype 1a and an IL28B non-CC genotype had undetectable HCV RNA. Across all dosing arms, HCV RNA remained undetectable 12 weeks after treatment completion in 100% of people with HCV genotype 4.In the response-guided therapy arm, 76% of early responders (who were treated for 12 weeks) and 67% of late responders (treated for 24 weeks) maintained undetectable HCV RNA 12 weeks after treatment completion, bringing the overall total to 72%.One death occurred during the trial—from sudden heart attack, in a participant with preexisting diabetes and hypertension—it was considered unrelated to study drugs. Adverse events were reported in virtually all study participants. Side effects from ritonavir, which is used to boost danoprevir levels, increased the likelihood of more than one serious adverse event among people in the danoprevir/r arms (range 4–9% vs. 1% for placebo). The rate of danoprevir/r-related treatment discontinuations was similar to the rate of PEG-IFN/RBV-associated discontinuations (3–7%, and 3–8%, respectively).Common side effects (experienced by more than 15% of study participants) included fatigue, fever, chills, weakness, nausea, diarrhea, itching, rash, hair loss, headache, aching muscles and joints, insomnia, cough, and appetite loss. Diarrhea was the only side effect associated with danoprevir/r. Adding danoprevir/r did not increase rates of rash or anemia (known side effects of other HCV protease inhibitors). Most grade 3 and grade 4 lab abnormalities were neutropenia, reported in 22% to 38% of study participants.

Hoffmann-La Roche and Genentech’s danoprevir/r (RG7227) is a twice-daily, ritonavir-boosted HCV protease inhibitor with activity against HCV genotypes 1, 4 and 6. DAUPHINE, an ongoing phase II trial in 421 treatment-naive people with HCV genotypes 1 and 4, is comparing doses (200, 100, and 50 mg danoprevir, boosted with 100 mg ritonavir, twice-daily) and response-guided therapy with danoprevir/r plus PEG-IFN/RBV. At 12 weeks after treatment completion, HCV RNA was undetectable in 86% of the highest-dosing arm, 77% of the 100 mg arm, and 65% of the 50 mg arm.Response to treatment in the 200 mg dosing arm did not differ according to HCV subtype or IL28B genotype; at 12 weeks after treatment completion, 88% of people with HCV subtype 1a and an IL28B non-CC genotype had undetectable HCV RNA. Across all dosing arms, HCV RNA remained undetectable 12 weeks after treatment completion in 100% of people with HCV genotype 4.In the response-guided therapy arm, 76% of early responders (who were treated for 12 weeks) and 67% of late responders (treated for 24 weeks) maintained undetectable HCV RNA 12 weeks after treatment completion, bringing the overall total to 72%.One death occurred during the trial—from sudden heart attack, in a participant with preexisting diabetes and hypertension—it was considered unrelated to study drugs. Adverse events were reported in virtually all study participants. Side effects from ritonavir, which is used to boost danoprevir levels, increased the likelihood of more than one serious adverse event among people in the danoprevir/r arms (range 4–9% vs. 1% for placebo). The rate of danoprevir/r-related treatment discontinuations was similar to the rate of PEG-IFN/RBV-associated discontinuations (3–7%, and 3–8%, respectively).Common side effects (experienced by more than 15% of study participants) included fatigue, fever, chills, weakness, nausea, diarrhea, itching, rash, hair loss, headache, aching muscles and joints, insomnia, cough, and appetite loss. Diarrhea was the only side effect associated with danoprevir/r. Adding danoprevir/r did not increase rates of rash or anemia (known side effects of other HCV protease inhibitors). Most grade 3 and grade 4 lab abnormalities were neutropenia, reported in 22% to 38% of study participants.Interferon-free DAA Combinations

Danoprevir/r and Mericitabine, plus Ribavirin (HCV Genotypes 1 and 4)

Roche’s phase IIb study, INFORM-SVR, is combining response-guided therapy with danoprevir/r, a twice-daily ritonavir-boosted HCV protease inhibitor, and mericitabine, a twice-daily nucleoside polymerase inhibitor, with or without ribavirin for 12 to 24 weeks in non-cirrhotic people with HCV genotype 1. The original study design was modified after high relapse rates were observed in the 12-week treatment and ribavirin-free arms. Treatment was extended to 24 weeks, and ribavirin was given to all participants.The majority of INFORM-SVR participants were male, had HCV genotype 1a, and non-CC genotypes. Of the 64 people treated for 24 weeks with all three drugs, 41% experienced SVR-12. People with HCV genotype 1b were more likely to achieve SVR-12 (71% versus 26% in HCV genotype 1a). In contrast, SVR-12 was more likely among people with non-CC genotypes (32% for CC versus 44% for non-CC), although only 4 people had HCV genotype 1b and CC genotype. Breakthrough rates were higher in people who did not receive ribavirin, and in HCV genotype 1a versus 1b. Resistance to danoprevir/r was observed in all patients who experienced viral breakthrough; mericitabine resistance was found in one person.Almost all participants had more than one adverse event; a total of 567 mild-to-moderate events were reported among 83 people. The most common side effects, occurring in >10% of people were headache, fatigue, nausea, diarrhea, colds, insomnia, itching, weakness, dizziness, irritability, shortness of breath, cough, upset stomach, painful joints, and vomiting. As for laboratory abnormalities, one person experienced grade 3 anemia, four people had grade 3 lipid elevations, and one case each of grade 3 elevations in phosphate and lipase were observed.A single serious adverse event, multiple myeloma, occurred 53 days after treatment completion and one person discontinued due to pain in the back of the throat (it was not specified whether or not this was a treatment-related adverse event).

- Everson G, Cooper C, Shiffman ML, et al. Rapid and sustained achievement of undetectable HCV RNA during treatment with ritonavir-boosted danoprevir/PEG-IFNa-2A/RBV in HCV genotype 1 or 4 patients: Dauphine week 36 interim analysis (Abstract 1177). Paper presented at: 47th Annual Meeting of the European Association for the Study of the Liver; 2012 April 18–22; Barcelona, Spain. Available from: http://mobile.ilcapp.eu/EASL_161/poster_24544/program.aspx. (Accessed 2012 June 25)

- Gane EJ, Pockros P, Zeuzem S, et al. Interferon-free treatment with combination of mericitabine and danoprevir/r with or without ribavirin in treatment-naïve HCV genotype-1 infected patients (Abstract 1412). 47th Annual Meeting of the European Association for the Study of the Liver; 2012 April 18–22; Barcelona, Spain. Available from:http://mobile.ilcapp.eu/EASL_161/poster_24848/program.aspx. (Accessed 2012 June 25)

Non- limiting examples of suitable HCV protease inhibitors include ACH-1095(Achillion), ACH-1625 (Achillion), ACH-2684 (Achillion), AVL-181 (Avila), AVL-192 (Avila), BI-201335 (Boehringer Ingelheim), BMS-650032 (BMS), boceprevir, danoprevir, GS- 9132 (Gilead), GS-9256 (Gilead), GS-9451 (Gilead), IDX-136 (Idenix), IDX-316 (Idenix), IDX- 320 (Idenix), MK-5172 (Merck), narlaprevir, PHX-1766 (Phenomix), telaprevir, TMC-435 (Tibotec), vaniprevir, VBY708 (Virobay), VX-500 (Vertex), VX-813 (Vertex), VX-985 (Vertex), or a combination thereof. Non-limiting examples of suitable HCV polymerase inhibitors include ANA-598 (Anadys), BI-207127 (Boehringer Ingelheim), BILB-1941 (Boehringer Ingelheim), BMS-791325 (BMS), filibuvir, GL59728 (Glaxo), GL60667 (Glaxo), GS-9669 (Gilead), IDX-375 (Idenix), MK-3281 (Merck), tegobuvir, TMC-647055 (Tibotec), VCH-759 (Vertex & ViraChem), VCH-916 (ViraChem), VX-222 (VCH-222) (Vertex & ViraChem), VX-759 (Vertex), GS-6620 (Gilead), IDX-102 (Idenix), IDX-184 (Idenix), INX-189 (Inhibitex), MK-0608 (Merck), PSI-938 (Pharmasset), RG7128 (Roche), TMC64912 (Medivir), GSK625433 (Glaxo SmithKline), BCX-4678 (BioCryst), ALS-2200 (Alios BioPharma/Vertex), ALS-2158 (Alios BioPharma/Vertex), or a combination thereof. A polymerase inhibitor may be a nucleotide polymerase inhibitor, such as GS-6620 (Gilead), IDX-102 (Idenix), IDX-184 (Idenix), INX-189 (Inhibitex), MK-0608 (Merck), PSI-938 (Pharmasset), RG7128 (Roche), TMC64912 (Medivir), ALS-2200 (Alios BioPharma/Vertex), ALS-2158 (Alios BioPharma/Vertex), or a combination therefore. A polymerase inhibitor may also be a non- nucleoside polymerase inhibitor, such as ANA-598 (Anadys), BI-207127 (Boehringer Ingelheim), BILB-1941 (Boehringer Ingelheim), BMS-791325 (BMS), filibuvir, GL59728 (Glaxo), GL60667 (Glaxo), GS-9669 (Gilead), IDX-375 (Idenix), MK-3281 (Merck), tegobuvir, TMC-647055 (Tibotec), VCH-759 (Vertex & ViraChem), VCH-916 (ViraChem), VX-222 (VCH-222) (Vertex & ViraChem), VX-759 (Vertex), or a combination thereof. Non-limiting examples of suitable NS5A inhibitors include GSK62336805 (Glaxo SmithKline), ACH-2928 (Achillion), AZD2836 (Astra-Zeneca), AZD7295 (Astra-Zeneca), BMS-790052 (BMS), BMS- 824393 (BMS), GS-5885 (Gilead), PPI-1301 (Presidio), PPI-461 (Presidio), or a combination thereof. Non-limiting examples of suitable cyclophilin inhibitors include alisporovir (Novartis & Debiopharm), NM-811 (Novartis), SCY-635 (Scynexis), or a combination thereof. Non-limiting examples of suitable HCV entry inhibitors include ITX-4520 (iTherx), ITX-5061 (iTherx), or a combination thereof.WO 2007015824WO 2003053349WO 2005095403WO 2005037214WO 2005095403WO 2005037214WO 2003053349WO 2007015824WO 2008128921US8048862 14 Apr 2009 1 Nov 2011 Intermune, Inc. Macrocyclic inhibitors of hepatitis C virus replication US8119592 10 Oct 2006 21 Feb 2012 Intermune, Inc. Compounds and methods for inhibiting hepatitis C viral replication US8232246 30 Jun 2009 31 Jul 2012 Abbott Laboratories Anti-viral compounds US8299021 19 Apr 2012 30 Oct 2012 Intermune, Inc. Macrocyclic inhibitors of hepatitis C virus replication US8420596 10 Sep 2009 16 Apr 2013 Abbott Laboratories Macrocyclic hepatitis C serine protease inhibitors WO2013106631A1 11 Jan 2013 18 Jul 2013 Abbvie Inc. Processes for making hcv protease inhibitors Danoprevir Clinical Trial Information( data fromhttp://clinicaltrials.gov)

NCT NUMBER RECRUITMENT CONDITIONS SPONSOR

/COLLABORATORSSTART DATE PHASES NCT01331850 Completed Hepatitis C, Chronic Hoffmann-La Roche 2011-05 Phase 2 NCT01531647 Completed Healthy Volunteer Hoffmann-La Roche 2012-01 Phase 1 NCT01588002 Completed Healthy Volunteer Hoffmann-La Roche 2012-04 Phase 1 NCT01592318 Active, not recruiting Healthy Volunteer Hoffmann-La Roche 2012-05 Phase 1 NCT01749150 Recruiting Hepatitis C, Chronic Hoffmann-La Roche 2013-04 Phase 2

- .............................................................................

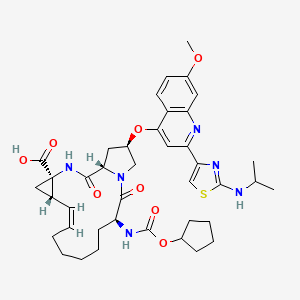

- 3 CILUPREVIR

CILUPREVIR(1S,4R,6S,7Z,14S,18R)-14- {[(cyclopentyloxy)carbonyl]amino}-18-[(7-methoxy-2- {2-[(propan-2-yl)amino]-1,3-thiazol-4-yl}quinolin-4- yl)oxy]-2,15-dioxo-3,16- diazatricyclo[14.3.0.0{4,6}]nonadec-7-ene-4- carboxylic acidCiluprevir, BILN-2061, BILN 2061, CHEBI:161337, BILN2061, BILN 2061ZW, BILN-2061-ZW,CAS , 300832-84-2Molecular Formula: C40H50N6O8S Molecular Weight: 774.9254

CILUPREVIR(1S,4R,6S,7Z,14S,18R)-14- {[(cyclopentyloxy)carbonyl]amino}-18-[(7-methoxy-2- {2-[(propan-2-yl)amino]-1,3-thiazol-4-yl}quinolin-4- yl)oxy]-2,15-dioxo-3,16- diazatricyclo[14.3.0.0{4,6}]nonadec-7-ene-4- carboxylic acidCiluprevir, BILN-2061, BILN 2061, CHEBI:161337, BILN2061, BILN 2061ZW, BILN-2061-ZW,CAS , 300832-84-2Molecular Formula: C40H50N6O8S Molecular Weight: 774.9254 Ciluprevir is used in the treatment of hepatitis C. It is manufactured by Boehringer Ingelheim Pharma GmbH & Co. KG under the research code of BILN-2061. It is targeted against NS2-3 protease.[1]Ciluprevir is an HCV NS3 protease inhibitor which had been in phase II clinical trials at Boehringer Ingelheim for the treatment of hepatitis C, however, no recent developments from the company have been reported.1. Challenge and Opportunity in Scaling-Up Metathesis Reaction: Synthesis of Ciluprevir (BILN 2061)Peter J. Dunn, et alhttp://onlinelibrary.wiley.com/doi/10.1002/9781118354520.ch10/summary

Ciluprevir is used in the treatment of hepatitis C. It is manufactured by Boehringer Ingelheim Pharma GmbH & Co. KG under the research code of BILN-2061. It is targeted against NS2-3 protease.[1]Ciluprevir is an HCV NS3 protease inhibitor which had been in phase II clinical trials at Boehringer Ingelheim for the treatment of hepatitis C, however, no recent developments from the company have been reported.1. Challenge and Opportunity in Scaling-Up Metathesis Reaction: Synthesis of Ciluprevir (BILN 2061)Peter J. Dunn, et alhttp://onlinelibrary.wiley.com/doi/10.1002/9781118354520.ch10/summary

DOI: 10.1002/9781118354520.ch10

2. Synthesis of BILN 2061, an HCV NS3 protease inhibitor with proven antiviral effect in humans

Org Lett 2004, 6(17): 2901

http://pubs.acs.org/doi/full/10.1021/ol0489907

3. Efficient synthesis of (S)-2-(cyclopentyloxycarbonyl)-amino-8-nonenoic acid: Key buiding block for BILN 2061, an HCV NS3 protease inhibitor

Org Process Res Dev 2007, 11(1): 60

4. Chinese Journal of Chemistry, 2011 , vol. 29, 7 pg. 1489 - 1502

DOI: 10.1002/cjoc.201180270

http://onlinelibrary.wiley.com/doi/10.1002/cjoc.201180270/abstract;jsessionid=F5F4331F5A95D00728394A254C2B1AE7.f01t04

................................

US 8222369

WO 2006071619

WO 2000059929

WO 2004092203

WO 2004039833

WO 2004037855

WO 2006036614

WO 2006033878

WO 2005042570

WO 2004093915

...................................................................................

https://www.google.co.in/patents/US8222369

.............................................................................

http://www.google.com/patents/WO2000059929A1

COMPD 822 IS CILUPREVIR IN TABLE 8

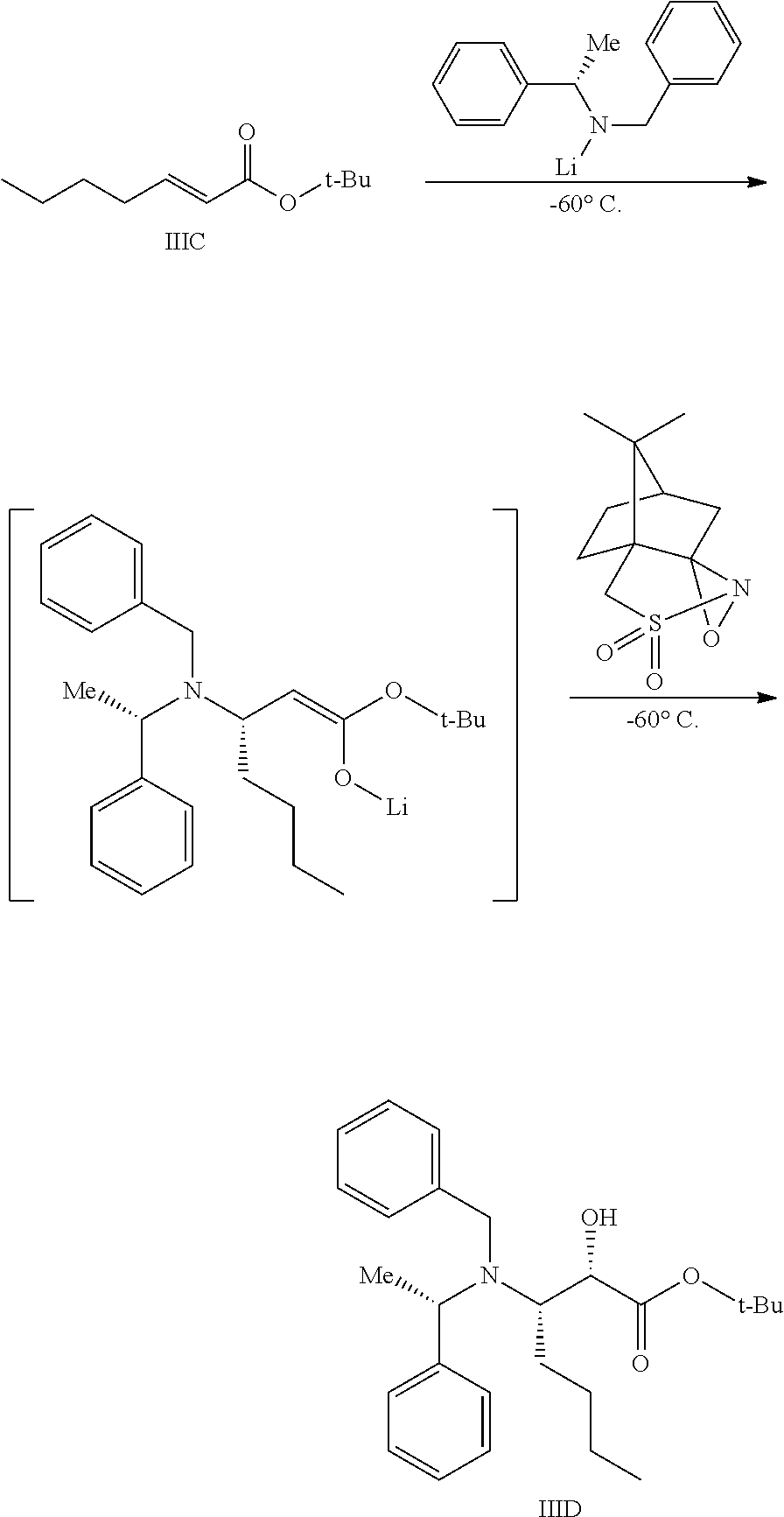

EXAMPLE 8 Synthesis of 4-hydroxy-7-methoxy-2[4(2-isopropylaminothiazolyl)] quinoline (8f ) Note: [ A variety of 2-alkylaminothiazolyl substituents were made using the same synthetic scheme where compound 8b was replaced by other alkyl thioureas.]

8b 8c 8d

A. The protocol used for the conversion of -anisidine to 8a was identical to that described in the literature: F.J. Brown et al. J. Med. Chem. 1989, 32 , 807-826. However, the purification procedure was modified to avoid purification by chromatography. The EtOAc phase containing the desired product was treated with a mixture of MgSO4, charcoal and 5% w/w (based on expected mass) silica gel. After filtration on celite, the product was triturated with ether. Compound 8a was obtained as a pale brown solid in >99% purity (as confirmed by HPLC).

B. A suspension of isopropyl thiourea (8b, 3.55 g, 30 mmol) and 3- bromopyruvic acid (8c, 5 g, 1 eq.) in dioxane (300 mL , 0.1 M) was heated to 80 °C.

Upon reaching 80 C the solution became clear and soon after the product precipitated as a white solid. After 2 hours of heating, the solution was cooled to RT and the white precipitate was filtered to obtain compound 8d in high purity (>98% purity as confirmed by NMR) and 94% yield (7.51 g). C. A mixture of the carboxylic acid 8d (4.85 g, 18.2 mmol) and the aniline derivative 8a (3 g, leq.) in pyridine (150 mL, 0.12 M) was cooled to -30 °C (upon cooling, the clear solution became partially a suspension). Phosphorus oxychloride (3.56 ml, 2.1 eq.) was then added slowly over a 5 min period. The reaction was stirred at -30 C for 1 h, the bath was removed and the reaction mixture was allowed to warm-up to RT. After 1.5 h the reaction mixture was poured into ice, the pH was adjusted to 11 with aqueous 3N NaOH, extracted with CH2C12, dried over anhydrous MgSO4, filtered and concentrated under vacuum. The beige solid was then purified by flash chromatography (45% EtOAc in hexane) to give compound 8e as a pale yellow solid in 73% yield (6.07 g). D. A solution of tBuOK (2.42 g, 21.6 mmol) in anhydrous tBuOH (40ml, 0.14 M, distilled from Mg metal) was heated to reflux. Compound 8e (1.8g, 5.4 mmol) was added portion-wise over 5 min and the dark red solution formed was stirred at reflux for an additional 20 min (completion of the reaction was monitored by HPLC). The mixture was cooled to RT and HCl was added (4 N in dioxane, 1.5 eq.). The mixture was then concentrated under vacuum, in order to assure that all of the

HCl and dioxane were removed, the product was re-dissolved twice in CH2C12 and dried under vacuum to finally obtain the HCl salt of compound 8f as a beige solid (1.62 g, 93% pure by HPLC). The product was then poured into a phosphate buffer

(IN NaH2PO4, pH=~4.5) and sonicated. The beige solid was filtered and dried under vacuum to give compound 8f (1.38 g, 81% yield) as a beige solid (91% pure by HPLC).

*H NMR (400 MHz, DMSO) δ 8.27 (s, IH), 8.12 (d, IH, J = 9.2 Hz), 7.97 (br.s, IH), 7.94 (s, IH), 7.43 (s, IH), 7.24 (dd, IH, J = 9.2, 2.2 Hz), 3.97 (m, IH), 3.94 (s, 3H), 1.24 (d, 2H, J = 6.4 Hz)

............

METHYL ESTER

EXAMPLE 34c

Using the same procedure as described in example 34 but reacting bromoketone 34f with commercially available N-iso-propylthiourea gave # 822

Η NMR (400 MHz, DMSO-d6) δ 8.63 (s, IH), 8.33-8.23 (bs, IH), 8.21 (d, J = 9.2 Hz, IH), 8.04 (d, J = 8.3 Hz, IH), 7.86 (bs, IH), 7.77 (s, IH), 7.35-7.23 (m, 2H), 5.81 (bs, IH), 5.52 (dd, J = 8.5 Hz, IH), 5.27 (dd, J = 9.2 Hz, IH), 4.65 (d, J = 11.8 Hz, IH), 4.51 (dd, J = 7.6 Hz, IH), 4.37 (bs, IH), 4.15 (bs, IH), 4.07-3.98 (m, 2H), 3.97 (s, 3H), 3.88 (d, J = 8.9 Hz, IH), 2.60-2.53 (m, 2H), 2.47-2.37 (m, 2H), 2.19-2.10 (dd, J = 9.2 Hz, IH), 1.80-1.64 (m, 2H), 1.63-1.29 (m, 13H), 1.27 and 1.25 (2 x d, J - 6.5 Hz, 6H), 1.23-1.09 (m, 2H). MS; es+: 775.0 (M + H)+, es : 772.9 (M - H)\

CILUPREVIR IS FREE ACID OF ABOVE AND HAS ENTRY 822 TABLE 8

.........

FREE AMINO COMPD

(Table 8)

A. To a solution of the macrocyclic intermediate 23b (13.05 g, 27.2 mmol, 1.0 eq.), Ph3P (14.28 g, 54.4 mmol, 2.0 eq) and 2-carboxymethoxy-4-hydroxy-7- methoxyquinoline (WO 00/09543 & WO 00/09558) (6.67 g, 28.6 mmol, 1.05 eq) in

THF (450 mL) at 0°C, DIAD (10.75 mL, 54.6 mmol, 2.0 eq) was added dropwise over a period of 15 min. The ice bath was then removed and the reaction mixture was stirred at RT for 3 h. After the complete conversion of starting material to products, the solvent was evaporated under vacuum, the remaining mixture diluted with

EtOAc, washed with saturated NaHCO3 (2x) and brine (lx), the organic layer was dried over anhydrous MgSO4, filtered and evaporated to dryness. Pure compound 34a was obtained after flash column chromatography; the column was eluted first with hexane/EtOAc (50:50), followed by CHCl3/EtOAc (95:5) to remove Ph3PO and

DIAD byproducts and elution of the impurities was monitored by TLC. Finally, the desired product 34a was eluted from the column with CHC13/ EtOAc (70:30).

Usually, the chromatography step had to be repeated 2-3 times before compound 34a could be isolated in high purity as a white solid with an overall yield of 68% (12.8 g, 99.5% pure by HPLC).

B. To a solution of the Boc-protected intermediate 34a (1.567g) in CH2C12 (15 mL), 4N HCl in dioxane (12 mL) was added and the reaction mixture was stirred at RT for 1 h. [In the event that a thick gel would form half way through the reaction period, an additional 10 mL CH2C12 was added.] Upon completion of the deprotection the solvents were evaporate to dryness to obtain a yellow solid and a paste like material. The mixture was redissolved in approximately 5% MeOH in

CH2C12 and re-evaporated to dryness under vacuum to obtain compound 34b as a yellow solid, which was used in the next step without any purification. C. To a solution of cyclopentanol (614 μL, 6.76 mmoL) in THF (15 mL), a solution of phosgene in toluene (1.93 M, 5.96 mL, 11.502 mmol) was added dropwise and the mixture was stirred at R.T. for 2 h to form the cyclopentyl chloroformate reagent (z). After that period, approximately half of the solvent was removed by evaporation under vacuum, the remaining light yellow solution was diluted by the addition of CH2C12 (5 mL) and concentrated to half of its original volume, in order to assure the removal of all excess phosgene. The above solution of the cyclopentyl chloroformate reagent was further diluted with THF (15 mL) and added to the amine-2HCl salt 34b. The mixture was cooled to 0 C in an ice bath, the pH was adjusted to -8.5-9 with the addition of Et3N (added dropwise) and the reaction mixture was stirred at 0 C for 1 h. After that period, the mixture was diluted with

EtOAc, washed with water (lx), saturated NaHCO3 (2x), H2O (2x) and brine (lx).

The organic layer was dried over anhydrous MgSO4, filtered and evaporated under vacuum to obtain a yellow-amber foam. Compound 34c was obtained as a white foam after purification by flash column chromatography (using a solvent gradient from 30% hexane to 20% hexane in EtOAc as the eluent) in 80% yield (1.27 g) and >93% purity. D. The dimethyl ester 34c (1.17g) was dissolved in a mixture of

THF/MeOH/H2O (20 mL, 2:1:1 ratio), and an aqueous solution of NaOH (1.8 mL,

IN, 1 eq.) was added. The reaction mixture was stirred at RT for 1 h before it was evaporated to dryness to obtain the sodium salt 34d as a white solid (-1.66 mmol). Compound 34d was used in the next step without purification.

E. The crude sodium salt 34d (1.66 mmoL) was dissolved in THF (17 mL), Et3N was added and the mixture was cooled to 0 C in an ice bath. Isobutylchloroformate

(322 μl, 2.5 mmol) was added dropwise and the mixture was stirred at 0 C for 75 min. After that period, diazomethane (15 mL) was added and stirring was continued at 0 C for 30 min and then at RT for an additional 1 h. Most of the solvent was evaporated to dryness under vacuum, the remaining mixture was diluted with EtOAc, washed with saturated NaHCO3 (2x), H2O (2x) and brine (lx), dried over anhydrous MgSO4, filtered and evaporated to dryness to obtain compound 34e as a light yellow foam (1.2g, -1.66 mmol). The diazoketone intermediate 34e was used in the next step without purification.

F. The diazoketone 34e (1.2g, 1.66 mmoL) dissolved in THF (17 mL) was cooled to 0 C in an ice bath. A solution of aqueous HBr (48%, 1.24 mL) was added dropwise and the reaction mixture was stirred at 0 C for 1 h. The mixture was then diluted with EtOAc, wash with saturated NaHCO3 (2x), H2O (2x) and brine (lx), the organic layer was dried over anhydrous MgSO4, filtered and evaporated to dryness to obtain the β-bromoketone intermediate 34f as a light yellow foam (-1.657 mmol).

G. To a solution of the bromoketone 34f (600 mg,0.779 mmol) in isopropanol (5 mL), thiourea (118 mg, 1.55 mmol) was added and the reaction mixture was placed in a pre-heated oil bath at 75 C where it was allowed to stir for 1 hr. The isopropanol was then removed under vacuum and the product dissolved in EtOAc

(100 mL). The solution was washed with saturated NaHCO3 and brine, the organic layer was dried over anhydrous Na2SO4, filtered and evaporated to afford the crude product 34g (522 mg) as a red-brown solid. This material was used in the final step without any further purification.

H. The crude methyl ester 34g (122 mg, 0.163 mmol) was dissolved in a solution of THF/MeOH/H2O (2:1:1 ratio, 4 mL) and saponified using LiOH»H2O (89 mg, 2.14 mmol). The hydrolysis reaction was carried out over a 12-15 h period at RT. The solvents were then removed under vacuum and the crude product purified by C18 reversed phase HPLC, using a solvent gradient from 10% CH3CN in H2O to 100%

CH3CN, to afford the HCV protease inhibitor #812 as a yellow solid (24 mg, 20% overall yield for the conversion of intermediate 34f to inhibitor #812).

*H NMR (400 MHz, DMSO-d6) δ 8.63 (s, IH), 8.26-8.15 (m, 2H), 7.79 (bs, IH), 7.72

(bs, IH), 7.50 (bs, 2H), 7.33-7.25 (m, 2H), 5.77 (bs, IH), 5.52 (dd, J = 8.3 Hz, IH), 5.27 (dd, J = 9.2 Hz, IH), 4.64 (d, J = 10.8 Hz, IH), 4.50 (dd, J = 8.3 Hz, IH), 4.39-4.31 (m, IH), 4.08-3.99 (m, 2H), 3.94 (s, 3H), 3.87 (d, J = 9.5 Hz, 2H), 2.65-2.53 (m, 2H), 2.46- 2.36 (m, 2H), 2.20-2.12 (dd, J = 8.6 Hz, IH), 1.80-1.64 (m, 2H), 1.63-1.06 (m, 14H). MS; es+: 733.2 (M + H)+, es": 731.2 (M - H)\

....................

http://www.google.com/patents/WO2006036614A2

(Z)-( 1S,4R, 14S, 18R)- 14-Cyclopentyloxycarbonylamino- 18-[2-(2- isopropylamino-thiazol-4-yl)-7-methoxy-quinolin-4-yloxy]-2,15-dioxo-3,16-diaza- tricyclo[14.3.0.0 ' ]nonadec-7-ene-4-carboxylic acid , whose chemical structure is as follows:

, provided for in Tsantrizos et al., U.S. Patent No. 6,608,027 Bl,

..............................

https://www.google.co.in/patents/WO2005090383A2

ENTRY 218

.......................

http://www.google.com/patents/WO2004039833A1

.................

nmr

Synthesis of BILN 2061, an HCV NS3 protease inhibitor with proven antiviral effect in humans

Org Lett 2004, 6(17): 2901

http://pubs.acs.org/doi/full/10.1021/ol0489907

http://pubs.acs.org/doi/suppl/10.1021/ol0489907/suppl_file/ol0489907si20040715_032207.pdf procedure

http://pubs.acs.org/doi/suppl/10.1021/ol0489907/suppl_file/ol0489907si20040715_032254.pdf nmr spectra

BILN 2061:

Methyl ester 18 (2.69 g, 3.41 mmol) was dissolved in a mixture of THF

(40 mL), MeOH (20 mL) and water (20 mL) and added LiOH.H2O (1.14 g, 27.3 mmol).The resulting mixture was left to stir at RT for 15 h. The solvents were then removedunder reduced pressure and the crude product was redissolved with EtOAc and dilutedwith brine. The pH of the aqueous layer was adjusted to 6 with aqueous HCl (1N) and theaqueous phase was extracted with EtOAc (3x). The combined organic phase werewashed with water, brine, dried over MgSO4 and concentrated under reduced pressure toafford BILN 2061 as a yellow solid (2.63 g, 99% yield). HPLC(A) 99%, MS m/z (ES+)773 (M+H)+, (ES-) 775 (M-H)-;

1H NMR (DMSO-d6) δ 8.63 (s, 1H), 8.26-8.15 (m, 2H),

7.79 (bs, 1H), 7.72 (bs, 1H), 7.50 (bs, 2H), 7.33-7.25 (m, 2H), 5.77 (bs, 1H), 5.52 (dd, J=8.3 Hz, 1H), 5.27 (dd, J= 9.2 Hz, 1H), 4.64 (d, J= 10.8 Hz, 1H), 4.50 (dd, J= 8.3 Hz, 1H),4.39-4.31 (m, 1H), 4.08-3.99 (m, 2H), 3.94 (s, 3H), 3.87 (d, J= 9.5 Hz, 2H), 2.65-2.53(m, 2H), 2.46-2.36 (m, 2H), 2.20-2.12 (dd, J= 8.6 Hz, 1H), 1.80-1.64 (m, 2H), 1.63-1.06(m, 14H); HRMS calcd for C40H51N6O8S: 775.3489; found: 775.3476

..............................

WO2007019674A1 Aug 3, 2006 Feb 22, 2007 Boehringer Ingelheim Int Viral polymerase inhibitors WO2010021717A2 * Aug 20, 2009 Feb 25, 2010 Sequoia Pharmaceuticals, Inc. Hcv protease inhibitors WO2010080874A1 Jan 7, 2010 Jul 15, 2010 Scynexis, Inc. Cyclosporine derivative for use in the treatment of hcv and hiv infection EP1455809A2 * Dec 13, 2002 Sep 15, 2004 Bristol-Myers Squibb Co. Inhibitors of hepatitis c virus EP2364984A1 Aug 28, 2006 Sep 14, 2011 Vertex Pharmaceuticals Incorporated Inhibitors of serine proteases EP2366704A1 Aug 28, 2006 Sep 21, 2011 Vertex Pharmaceuticals Incorporated Inhibitors of serine proteases US7368452 Jul 18, 2006 May 6, 2008 Enanta Pharmaceuticals, Inc. Quinoxalinyl macrocyclic hepatitis C serine protease inhibitors US7608590 Jan 28, 2005 Oct 27, 2009 Medivir Ab HCV NS-3 serine protease inhibitors US7671032 Jan 28, 2005 Mar 2, 2010 Medivir Ab HCV NS-3 serine protease inhibitors US7816348 Jan 29, 2007 Oct 19, 2010 Boehringer Ingelheim International Gmbh Viral polymerase inhibitors US7897622 Aug 10, 2007 Mar 1, 2011 Boehringer Ingelheim International Gmbh Viral polymerase inhibitors US8148399 Jul 28, 2006 Apr 3, 2012 Tibotec Pharmaceuticals Ltd. Macrocyclic inhibitors of hepatitis C virus US8153800 Aug 3, 2011 Apr 10, 2012 Tibotec Pharmaceuticals Ltd. Macrocyclic inhibitors of hepatitis C virus US8242140 Jul 31, 2008 Aug 14, 2012 Boehringer Ingelheim International Gmbh Viral polymerase inhibitors US8349869 Mar 6, 2012 Jan 8, 2013 Tibotec Pharmaceuticals Ltd. Macrocylic inhibitors of hepatitis C virus US8476257 Dec 3, 2008 Jul 2, 2013 Boehringer Ingelheim International Gmbh Viral polymerase inhibitors US8541402 May 3, 2012 Sep 24, 2013 Boehringer Ingelheim International Gmbh Viral polymerase inhibitors WO2000059929A1 * Apr 3, 2000 Oct 12, 2000 Boehringer Ingelheim Ca Ltd Macrocyclic peptides active against the hepatitis c virus WO2003053349A2 * Dec 13, 2002 Jul 3, 2003 Squibb Bristol Myers Co Inhibitors of hepatitis c virus WO2003064455A2 * Jan 24, 2003 Aug 7, 2003 Boehringer Ingelheim Ca Ltd Macrocyclic peptides active against the hepatitis c virus WO2003066103A1 * Feb 5, 2003 Aug 14, 2003 Boehringer Ingelheim Pharma Pharmaceutical compositions for hepatitis c viral protease inhibitors - .......................................................................................................

- ......................................................................................................................

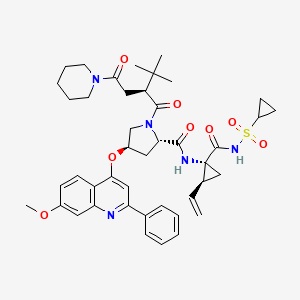

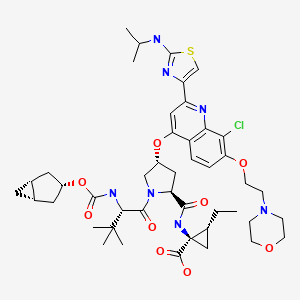

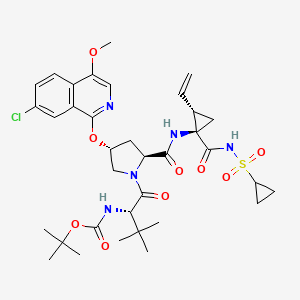

- 4 SOVAPREVIR

- SOVAPREVIR(2S, 4R) -1 - [(2S)-2-tert-butyl-4-oxo-4-(piperidin-1-yl) butanoyl]-N-{(1R, 2S) -1 - [(cyclopropanesulfonyl) carbamoyl]-2-ethenylcyclopropyl} -4 - [(7-methoxy-2-phenylquinolin-4-yl) oxy] pyrrolidine-2-carboxamidePATENTUS 2009048297 ENTRY 60WO 2008008502CN 103420991THERAPEUTIC CLAIM ....Treatment of hepatitis CCHEMICAL NAMES1. 2-Pyrrolidinecarboxamide, N-[(1R,2S)-1-[[(cyclopropylsulfonyl)amino]carbonyl]-2-

ethenylcyclopropyl]-1-[(2S)-3,3-dimethyl-1-oxo-2-[2-oxo-2-(1-piperidinyl)ethyl]butyl]-4-

[(7-methoxy-2-phenyl-4-quinolinyl)oxy]-, (2S,4R)-2. (2S,4R)-N-{(1R,2S)-1-[(cyclopropylsulfonyl)carbamoyl]-2-ethenylcyclopropyl}-1-{(2S)-

3,3-dimethyl-2-[2-oxo-2-(piperidin-1-yl)ethyl]butanoyl}-4-[(7-methoxy-2-phenylquinolin-

4-yl)oxy]pyrrolidine-2-carboxamideMOLECULAR FORMULA C43H53N5O8SMOLECULAR WEIGHT 800.0SPONSOR Achillion Pharmaceuticals, Inc.CODE DESIGNATION ACH-0141625CAS REGISTRY NUMBER 1001667-23-7- ACH-0141625

- Sovaprevir

- UNII-2ND9V3MN6O

Sovaprevir (formerly ACH-0141625), an HCV NS3 protease inhibitor, is in phase II clinical trials at Achillion for the oral treatment of naive patients with chronic hepatitis C virus genotype 1.In 2012, fast track designation was assigned by the FDA for the treatment of hepatitis C (HCV). In 2013, a clinical hold was placed for the treatment of hepatitis C (HCV) in combination with atazanavir after elevations in liver enzymes associated with the combination of both compounds.Sovaprevir, previously referred to as ACH-1625, is an investigational, next-generation NS3/4A protease inhibitor discovered by Achillion that is currently on clinical hold. In 2012, Fast Track status was granted by the U.S. Food and Drug Administration (FDA) to sovaprevir for the treatment of chronic hepatitis C viral infection (HCV).Achillion has initiated a Phase 2 clinical trial (007 Study) to evaluate the all-oral, interferon-free combination of sovaprevir and its second-generation NS5A inhibitor, ACH-3102, with ribavirin (RBV), for a 12 week treatment duration, in treatment naïve, genotype 1 (GT1) HCV patients. In July 2013, sovaprevir was placed on clinical hold after elevated liver enzymes were observed in a Phase 1 healthy subject drug-drug interaction study evaluating the effects of concomitant administration of sovaprevir with ritonavir-boosted atazanavir.In accordance with the clinical hold, the FDA provided that no new clinical trials that included dosing with sovaprevir could be initiated, however, the FDA allowed continued enrollment and treatment of patients in the Phase 2 -007 clinical trial evaluating 12-weeks of sovaprevir in combination with ACH-3102 and RBV for patients with treatment-naive genotype 1 HCV. In September 2013, after reviewing Achillion's response, the FDA stated that although all issues identified in the June 2013 letter had been addressed, it had concluded that the removal of the clinical hold was not warranted at this time.The FDA requested, among other things, additional analysis to more fully characterize sovaprevir pharmacokinetics and the intrinsic and extrinsic factors that may lead to higher than anticipated exposures of sovaprevir or other potential toxicities in addition to the observed liver enzyme elevations.The FDA also requested Achillion's proposed plan for future clinical trials in combination with other directly-acting antivirals. At the request of the FDA, Achillion plans to submit a proposed plan for analyzing the additional clinical, non-clinical and pharmacokinetic data requested before the end of 2013, and if that analysis plan is approved by the FDA, submit a complete response during the first half of 2014. Achillion retains worldwide commercial rights to sovaprevir.Sovaprevir has demonstrated activity against all HCV genotypes (GT), including equipotent activity against both GT 1a and 1b (IC50 ~ 1nM) in vitro.With its rapid and extensive partitioning to the liver, as well as high liver/plasma ratios, sovaprevir has been clinically demonstrated to allow for once-daily, non-boosted dosing.The current safety database for sovaprevir includes more than 560 subjects dosed to date and demonstrates that sovaprevir is well tolerated in these subjects.

Sovaprevir has demonstrated high rates of clinical cures in combination with pegylated-interferon and RBV in a challenging, real world, patient population of genotype 1 treatment-naive patients.100% of GT1b subjects achieved a rapid virologic response (RVR) in the 007 Study evaluating the interferon-free combination of sovaprevir + ACH-3102 + RBV for 12 weeks. The Phase 2 study is ongoing.Sovaprevir in vitro retains activity against mutations that confer resistance to 1st-generation protease inhibitors.In clinical studies to date, sovaprevir has demonstrated a high pharmacologic barrier to resistance with no on-treatment viral breakthrough reported to date in GT1b patients.Sovaprevir is believed to be synergistic when combined with other classes of DAAs, including the second-generation NS5A inhibitor, ACH-3102.For more information about the next-generation NS3/4A protease inhibitor, sovaprevir, please see the Related Links on this page or visit Resources.Sovaprevir is an investigational compound. Its safety and efficacy have not been established. (Updated December 2013)SOVAPREVIRAn estimated 3% of the world's population is infected with the hepatitis C virus. Of those exposed to HCV, 80% become chronically infected, at least 30% develop cirrhosis of the liver and 1-4% develop hepatocellular carcinoma. Hepatitis C Virus (HCV) is one of the most prevalent causes of chronic liver disease in the United States, reportedly accounting for about 15 percent of acute viral hepatitis, 60 to 70 percent of chronic hepatitis, and up to 50 percent of cirrhosis, end-stage liver disease, and liver cancer. Chronic HCV infection is the most common cause of liver transplantation in the U.S., Australia, and most of Europe. Hepatitis C causes an estimated 10,000 to 12,000 deaths annually in the United States. While the acute phase of HCV infection is usually associated with mild symptoms, some evidence suggests that only about 15% to 20% of infected people will clear HCV.HCV is an enveloped, single-stranded RNA virus that contains a positive-stranded genome of about 9.6 kb. HCV is classified as a member of the Hepacivirus genus of the family Flaviviridae. At least 4 strains of HCV, GT-1-GT-4, have been characterized.The HCV lifecycle includes entry into host cells; translation of the HCV genome, polyprotein processing, and replicase complex assembly; RNA replication, and virion assembly and release. Translation of the HCV RNA genome yields a more than 3000 amino acid long polyprotein that is processed by at least two cellular and two viral proteases. The HCV polyprotein is:NH2-C-E1-E2-p7-NS2-NS3-NS4A-NS4B-NS5A-NS5B-COOH.The cellular signal peptidase and signal peptide peptidase have been reported to be responsible for cleavage of the N-terminal third of the polyprotein (C-E1-E2-p7) from the nonstructural proteins (NS2-NS3-NS4A-NS4B-NS5A-NS5B). The NS2-NS3 protease mediates a first cis cleavage at the NS2-NS3 site. The NS3-NS4A protease then mediates a second cis-cleavage at the NS3-NS4A junction. The NS3-NS4A complex then cleaves at three downstream sites to separate the remaining nonstructural proteins. Accurate processing of the polyprotein is asserted to be essential for forming an active HCV replicase complex.Once the polyprotein has been cleaved, the replicase complex comprising at least the NS3-NS5B nonstructural proteins assembles. The replicase complex is cytoplasmic and membrane-associated. Major enzymatic activities in the replicase complex include serine protease activity and NTPase helicase activity in NS3, and RNA-dependent RNA polymerase activity of NS5B. In the RNA replication process, a complementary negative strand copy of the genomic RNA is produced. The negative strand copy is used as a template to synthesize additional positive strand genomic RNAs that may participate in translation, replication, packaging, or any combination thereof to produce progeny virus. Assembly of a functional replicase complex has been described as a component of the HCV replication mechanism. Provisional application 60/669,872 “Pharmaceutical Compositions and Methods of Inhibiting HCV Replication” filed Apr. 11, 2005, is hereby incorporated by reference in its entirety for its disclosure related to assembly of the replicase complex.Current treatment of hepatitis C infection typically includes administration of an interferon, such as pegylated interferon (IFN), in combination with ribavirin. The success of current therapies as measured by sustained virologic response (SVR) depends on the strain of HCV with which the patient is infected and the patient's adherence to the treatment regimen. Only 50% of patients infected with HCV strain GT-1 exhibit a sustained virological response. Direct acting antiviral agents such as ACH-806, VX-950 and NM 283 (prodrug of NM 107) are in clinical development for treatment of chronic HCV. Due to lack of effective therapies for treatment for certain HCV strains and the high mutation rate of HCV, new therapies are needed.................................................(2S,4R)-1-((S)-2-tert-butyl-4-oxo-4-(piperidin-1-yl)butanoyl)-N-((1R,2S)-1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-2-carboxamide SOVAPREVIR IS DESCRIBED AS 60 IN CLAIMSYNTHESIS OF INTERMEDIATE 13 BELOW AND ALSO COMPD 8 IE SOVAPREVIR IN STEP 4Example 1SYNTHESIS OF 1-((2S,4R)-1-((S)-2-TERT-BUTYL-4-OXO-4-(PIPERIDIN-1-YL)BUTANOYL)-4-(7-METHOXY-2-PHENYLQUINOLIN-4-YLOXY)PYRROLIDINE-2-CARBOXAMIDO)-2-VINYLCYCLOPROPANECARBOXYLIC ACIDStep 1. Preparation of N-(cyclopropylsulfonyl)-1-(BOC-amino)-2-vinylcyclopropanecarboxamideCDI (2.98 g, 18.4 mm, 1.1 eq) is dissolved in ethyl acetate. N-Boc-cyclopropylvinyl acid (3.8 g, 16.7 mm, 1.0 eq), prepared via the procedure given by Beaulieu, P. L. et al. (J. Org. Chem. 70: 5869-79 (2005)) is added to the CDI/ethyl acetate mixture and stirred at RT until the starting material is consumed. Cyclopropyl sulfonamine (2.2 g, 18.4 mm, 1.1 eq) is added to this mixture followed by DBU (2.1 ml, 20.5 mm, 1.23 eq) and the mixture is stirred at RT for 2 h. Workup and purification by silica gel chromatography provides 2g of compound 2.Step 2. Preparation of (2S,4R)-tert-butyl 2-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carboxylate and (2S,4R)—N-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-2-carboxamideCompound 1 (4.3 g, 9.3 mmol, 1.1 eq), prepared according to the method given ins WO 02/060926, in DMF is stirred with O-(Benzotriazol-lyl)-N,N,N′,N′-Tetramethyluronium hexafluorophosphate (4.1 g, 10.5 mmol, 1.3 eq) for 30 minutes, followed by addition of cyclopropylamine 2 (1.92 g, 8.3 mmol, 1.0 eq) and N-methylmorpholine (2.52 g, 25.0 mmol, 3.0 eq). The mixture is stirred over night and the solvent removed under reduced pressure. The resulting residue is diluted with ethyl acetate and washed with saturated aqueous NaHCO3. The organic solvent is dried over MgSO4 and concentrated under reduced pressure to afford crude 3, which is used for next step without further purification.Compound 3 in 10 ml dry CH2Cl2 is treated with 5 mL TFA and stirred over night. The solvent is removed and the residue recrystallized from ethyl acetate to afford 4.12 g Compound 4 (61% yield two steps).Step 3. Preparation of (3S)-3-((2S,4R)-2-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidThe Acid 5 (58 mg, 0.25 mmol, 1.2 eq), prepared via the procedure given by Evans, D. A., et al. (J. Org. Chem. 64: 6411-6417 (1999)) in 1.2 mL DMF is stirred with 4 (138 mg, 0.21 mmol), HATU (160 mg, 0.42 mmol, 2.0 eq), and DIEA (0.63 mmol, 3.0 eq) overnight. The mixture is subjected to HPLC purification to afford 121 mg 6 (77% yield), which is further treated with 0.5 mL TFA in 1.0 mL DCM overnight. The solvent was removed to provide Compound 7 in 100% yield.Step 4. Preparation of (2S,4R)-1-((S)-2-tert-butyl-4-oxo-4-(piperidin-1-yl)butanoyl)-N-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-2-carboxamidePLEASE NOTE 8 IS SOVAPREVIRThe Acid 7 (0.15 mmol) in 1.0 mL DMF is stirred with pepridine (excess, 0.6 mmol, 4 eq), HATU (115 mg, 0.3 mmol, 2.0 eq), and DIEA (0.45 mmol, 3.0 eq) for 4 hrs. The mixture is subjected to HPLC purification to afford 77.1 mg 8.Step 5. Preparation of (3S)-3-((2S,4R)-2-(1-(ethoxycarbonyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidStep 5. Preparation of (3S)-3-((2S,4R)-2-(1-(ethoxycarbonyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidThe Acid 5 (105 mg, 0.46 mmol, 1.2 eq) in 1.2 mL DMF is stirred with 9 (202 mg, 0.38 mmol), HATU (290 mg, 0.76 mmol, 2.0 eq), and DIEA (1.2 mmol, 3.0 eq) overnight. The mixture is subjected to HPLC purification to afford 204.3 mg 10 (75% yield), which is further treated with 0.5 mL TFA in 1.0 mL DCM overnight. The solvent is removed to provide 11 in 100% yield.Step 6. Preparation of Final ProductThe Acid 11 (30 mg, 0.045 mmol) in 1.0 mL DMF is stirred with pepridine (0.27 mmol, 6 eq), HATU (34 mg, 0.09 mmol, 2.0 eq), and DIEA (0.14 mmol, 3.0 eq) for 2 hrs. The mixture is subjected to HPLC purification to afford 21.2 mg 12 (65% yield), which is hydrolyzed in methanol with 2N NaOH for 6 hrs. The mixture is acidified with 6N HCl and subjected to HPLC purification to afford 7.6 mg 13.....................................

SOVAPREVIR IS DESCRIBED AS 60 IN CLAIMSYNTHESIS OF INTERMEDIATE 13 BELOW AND ALSO COMPD 8 IE SOVAPREVIR IN STEP 4Example 1SYNTHESIS OF 1-((2S,4R)-1-((S)-2-TERT-BUTYL-4-OXO-4-(PIPERIDIN-1-YL)BUTANOYL)-4-(7-METHOXY-2-PHENYLQUINOLIN-4-YLOXY)PYRROLIDINE-2-CARBOXAMIDO)-2-VINYLCYCLOPROPANECARBOXYLIC ACIDStep 1. Preparation of N-(cyclopropylsulfonyl)-1-(BOC-amino)-2-vinylcyclopropanecarboxamideCDI (2.98 g, 18.4 mm, 1.1 eq) is dissolved in ethyl acetate. N-Boc-cyclopropylvinyl acid (3.8 g, 16.7 mm, 1.0 eq), prepared via the procedure given by Beaulieu, P. L. et al. (J. Org. Chem. 70: 5869-79 (2005)) is added to the CDI/ethyl acetate mixture and stirred at RT until the starting material is consumed. Cyclopropyl sulfonamine (2.2 g, 18.4 mm, 1.1 eq) is added to this mixture followed by DBU (2.1 ml, 20.5 mm, 1.23 eq) and the mixture is stirred at RT for 2 h. Workup and purification by silica gel chromatography provides 2g of compound 2.Step 2. Preparation of (2S,4R)-tert-butyl 2-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carboxylate and (2S,4R)—N-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-2-carboxamideCompound 1 (4.3 g, 9.3 mmol, 1.1 eq), prepared according to the method given ins WO 02/060926, in DMF is stirred with O-(Benzotriazol-lyl)-N,N,N′,N′-Tetramethyluronium hexafluorophosphate (4.1 g, 10.5 mmol, 1.3 eq) for 30 minutes, followed by addition of cyclopropylamine 2 (1.92 g, 8.3 mmol, 1.0 eq) and N-methylmorpholine (2.52 g, 25.0 mmol, 3.0 eq). The mixture is stirred over night and the solvent removed under reduced pressure. The resulting residue is diluted with ethyl acetate and washed with saturated aqueous NaHCO3. The organic solvent is dried over MgSO4 and concentrated under reduced pressure to afford crude 3, which is used for next step without further purification.Compound 3 in 10 ml dry CH2Cl2 is treated with 5 mL TFA and stirred over night. The solvent is removed and the residue recrystallized from ethyl acetate to afford 4.12 g Compound 4 (61% yield two steps).Step 3. Preparation of (3S)-3-((2S,4R)-2-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidThe Acid 5 (58 mg, 0.25 mmol, 1.2 eq), prepared via the procedure given by Evans, D. A., et al. (J. Org. Chem. 64: 6411-6417 (1999)) in 1.2 mL DMF is stirred with 4 (138 mg, 0.21 mmol), HATU (160 mg, 0.42 mmol, 2.0 eq), and DIEA (0.63 mmol, 3.0 eq) overnight. The mixture is subjected to HPLC purification to afford 121 mg 6 (77% yield), which is further treated with 0.5 mL TFA in 1.0 mL DCM overnight. The solvent was removed to provide Compound 7 in 100% yield.Step 4. Preparation of (2S,4R)-1-((S)-2-tert-butyl-4-oxo-4-(piperidin-1-yl)butanoyl)-N-(1-(cyclopropylsulfonylcarbamoyl)-2-vinylcyclopropyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-2-carboxamidePLEASE NOTE 8 IS SOVAPREVIRThe Acid 7 (0.15 mmol) in 1.0 mL DMF is stirred with pepridine (excess, 0.6 mmol, 4 eq), HATU (115 mg, 0.3 mmol, 2.0 eq), and DIEA (0.45 mmol, 3.0 eq) for 4 hrs. The mixture is subjected to HPLC purification to afford 77.1 mg 8.Step 5. Preparation of (3S)-3-((2S,4R)-2-(1-(ethoxycarbonyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidStep 5. Preparation of (3S)-3-((2S,4R)-2-(1-(ethoxycarbonyl)-2-vinylcyclopropylcarbamoyl)-4-(7-methoxy-2-phenylquinolin-4-yloxy)pyrrolidine-1-carbonyl)-4,4-dimethylpentanoic acidThe Acid 5 (105 mg, 0.46 mmol, 1.2 eq) in 1.2 mL DMF is stirred with 9 (202 mg, 0.38 mmol), HATU (290 mg, 0.76 mmol, 2.0 eq), and DIEA (1.2 mmol, 3.0 eq) overnight. The mixture is subjected to HPLC purification to afford 204.3 mg 10 (75% yield), which is further treated with 0.5 mL TFA in 1.0 mL DCM overnight. The solvent is removed to provide 11 in 100% yield.Step 6. Preparation of Final ProductThe Acid 11 (30 mg, 0.045 mmol) in 1.0 mL DMF is stirred with pepridine (0.27 mmol, 6 eq), HATU (34 mg, 0.09 mmol, 2.0 eq), and DIEA (0.14 mmol, 3.0 eq) for 2 hrs. The mixture is subjected to HPLC purification to afford 21.2 mg 12 (65% yield), which is hydrolyzed in methanol with 2N NaOH for 6 hrs. The mixture is acidified with 6N HCl and subjected to HPLC purification to afford 7.6 mg 13.....................................

- ..................................................................................................

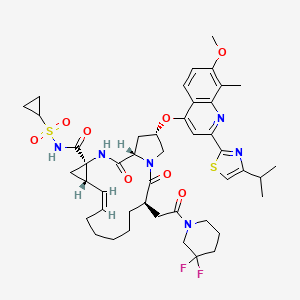

- 5 VEDROPREVIR